Filament Handling

End of Filament Handling

I figured I would post this so others could learn from it (although I know they have been told). I had a printer dropped off to fix along with a roll of filament to use to print some of Tim's boxes. As the roll was being handed to me I noticed the end of the filament was loose and i made sure to instruct on the proper way to tuck the unused end in the holes in the side of the spool to keep from getting a knot and jamming during a print. Hours later I got the printer fixed and was trying to get a box print started so I could go to bed (1am now). Everything was looking good so I went to bed.

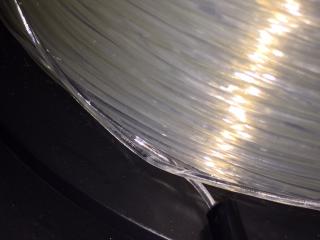

I woke up this morning and went to check on the print progress knowing that I would not have time to start another one before leaving for work since it started so late and my heart sank after seeing that only 1/2" or so had been printed, which looked good I might add. I looked around to see what could be the problem and noticed a big knot right where the filament goes into the guide tube. This is what happens if you let go of the end of the filament and don't immediately tuck it in the holes in the side of the spool. That is what the holes are for, so use them. I always unload the filament by pulling on it with one hand and wind it up with another but never let go of the end until it is secured. One evening wasted.

Not pointing fingers because know one knows how the spool was handled, just trying to make a point for all to learn.